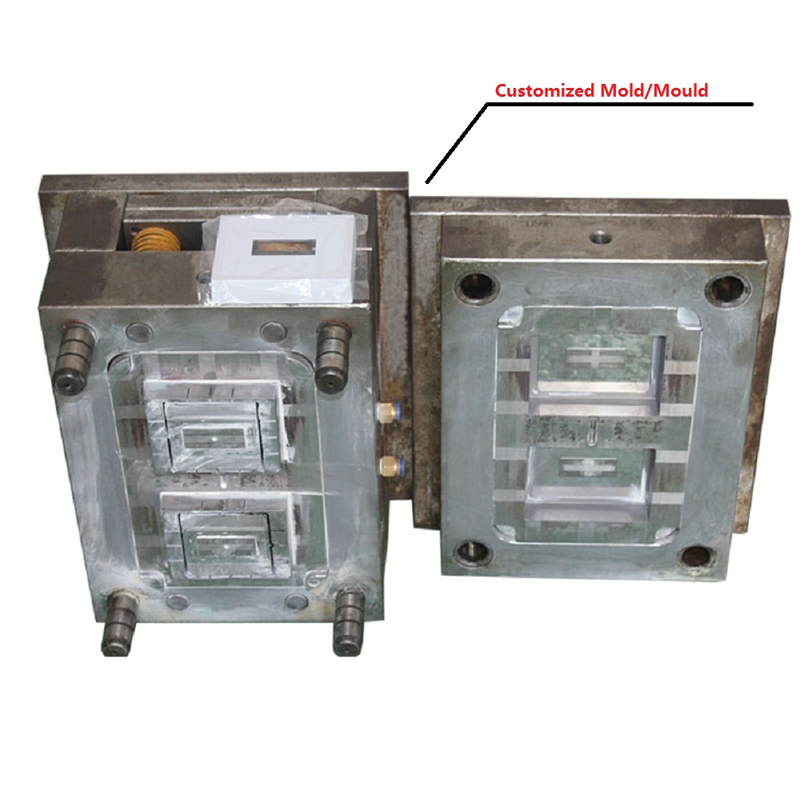

When it comes to plastic injection molding, all molds can be customized to meet unique requirements. The mold's customization is what makes this production method highly efficient, as it allows manufacturers to produce accurate and precise products. Customizing the mold also makes it possible to produce products in different shapes, sizes, and designs, which is useful for creating a wide range of plastic parts.

The mold's steel type plays a significant role in determining the quality and precision of the final product. Different steels are used depending on the desired product's size, shape, and complexity. Some of the commonly used steels in plastic injection molding include NAK80, AISI, KOBE, JIS, S50C, P20, H13, 1.2738, 1.2311, 718, and 718HH. Each of these steels is suitable for specific plastic molding needs, making it essential to choose the appropriate one.

Besides the steel type, another essential factor to consider when producing plastic parts using injection molding is the choice of plastic materials. Some of the commonly used plastic materials include Hyterl TPEE, PA66, ABS, PP, POM, PC, TPR, HDPE, and PS. Choosing the right plastic material is crucial as it affects the final product's quality, durability, and functionality.

Working with a professional Chinese plastic injection tooling company ensures that you get high-quality molds tailored to your specific production needs. Such companies offer a range of services, including design, prototyping, mold making, and injection molding. Professional Chinese plastic injection tooling companies use the latest technology and equipment, ensuring that they produce high-quality molds that meet or exceed their clients' expectations.

In conclusion, plastic injection molding is an efficient and reliable production method for producing plastic parts. Customizing the mold, choosing the right steel type, and plastic material all play a vital role in producing high-quality products. Working with professional Chinese plastic injection tooling companies ensures that you get the best molds tailored to your unique production needs. So, ensure you choose a reputable plastic injection tooling company for your injection molding needs.